Modern construction has undergone dramatic evolution over the past century, with innovations in materials and techniques reshaping skylines worldwide. Among these advancements, structural steel stands out as the backbone of contemporary architecture and engineering. From towering skyscrapers and expansive bridges to industrial complexes and residential projects, structural steel provides the strength, flexibility, and sustainability that modern construction demands. This is why structural steel suppliers in India play such a critical role in fueling the nation’s infrastructure growth.

What Makes Structural Steel Unique?

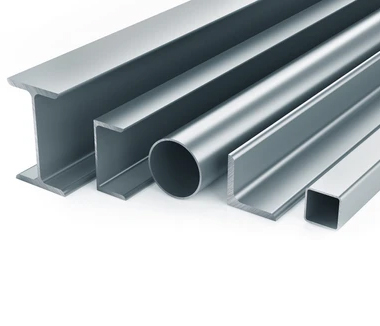

Structural steel is a category of steel designed specifically for construction purposes. Unlike ordinary steel, it is engineered to withstand immense loads, resist environmental stress, and provide long lasting durability. Its unique properties make it indispensable in projects where safety, efficiency, and longevity are paramount.

Key Characteristics Include:

- High strength to weight ratio: Structural steel offers exceptional strength without excessive weight, allowing architects to design taller and more complex structures.

- Versatility: It can be molded into different shapes and sizes, making it suitable for a wide range of applications.

- Durability: When treated properly, structural steel is resistant to corrosion and wear, ensuring a long service life.

- Recyclability: Steel is one of the most widely recycled materials in the world, aligning with sustainability goals.

Structural Steel in Modern Construction

The role of structural steel in construction is evident in some of the world’s most iconic projects. Skyscrapers like the Burj Khalifa, bridges such as the Golden Gate, and countless industrial plants rely on steel frameworks for stability and resilience. In India, rapid urbanization and infrastructure development have further amplified the demand for structural steel.

Applications Include:

- High-rise buildings: Steel frames enable vertical expansion without compromising safety.

- Bridges and flyovers: Structural steel provides the tensile strength needed to span long distances.

- Industrial facilities: Factories, warehouses, and plants depend on steel for robust frameworks.

- Residential projects: Modern housing increasingly incorporates steel for durability and design flexibility.

The Importance of Structural Steel Suppliers in India

India’s booming construction industry relies heavily on reliable suppliers to meet its growing demand for structural steel. Structural Steel suppliers in India ensure that projects across the country have access to high quality materials that meet international standards. Their role is not limited to providing steel; they also contribute to innovation, sustainability, and cost-effective solutions.

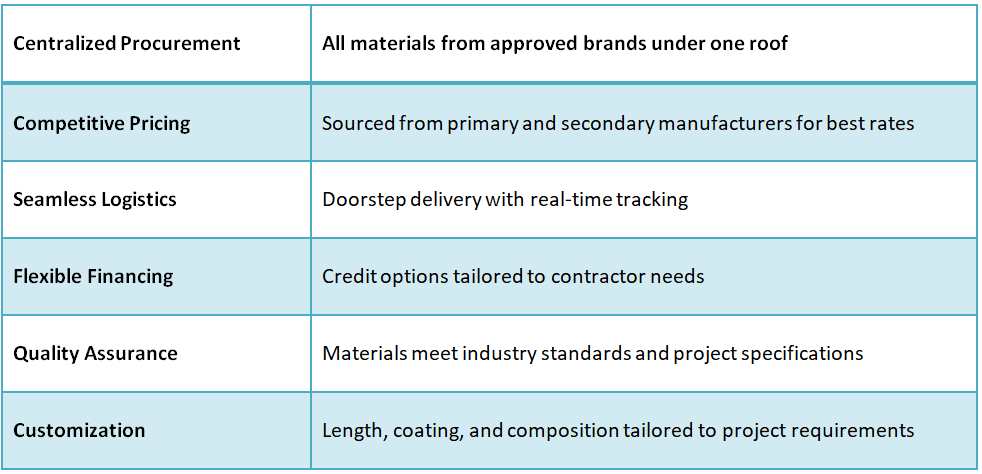

Benefits of Working with Trusted Suppliers:

- Quality assurance: Suppliers adhere to strict standards, ensuring safety and reliability.

- Timely delivery: Construction projects depend on punctual supply chains to avoid delays.

- Customization: Suppliers provide tailored solutions to meet specific project requirements.

- Sustainability practices: Many suppliers focus on ecofriendly production and recycling.

Why Structural Steel is the Backbone of Modern Construction?

Structural steel is considered the backbone of modern construction for several reasons:

- Strength and stability: It supports massive loads, making it ideal for largescale projects.

- Design flexibility: Architects can experiment with innovative designs thanks to steel’s adaptability.

- Speed of construction: Prefabricated steel components significantly reduce construction time.

- Cost efficiency: Long-term durability and reduced maintenance make steel a co-steffective choice.

- Safety: Steel structures are resistant to fire, earthquakes, and extreme weather conditions when properly engineered.

Sustainability and the Future of Steel

As the world moves toward sustainable development, structural steel aligns perfectly with ecofriendly goals. Its recyclability reduces waste, while modern production techniques minimize carbon footprints. In India, where infrastructure growth must balance environmental concerns, structural steel offers a responsible solution.

Future Trends Include:

- Green steel production: Using renewable energy and low carbon processes.

- Smart integration: Combining steel frameworks with smart building technologies.

- Hybrid materials: Blending steel with composites for enhanced performance.

Conclusion

Structural steel has earned its reputation as the backbone of modern construction by delivering unmatched strength, versatility, and sustainability. With India’s rapid urbanization and infrastructure expansion, the role of Structural Steel suppliers in India becomes even more vital. They ensure that builders, architects, and engineers have access to the materials needed to create safe, innovative, and future ready structures.

If you’re looking to partner with trusted suppliers who understand the demands of modern construction, visit zhuzoor.com today. Discover how their expertise and solutions can help you build stronger, smarter, and more sustainable projects.

READ POST